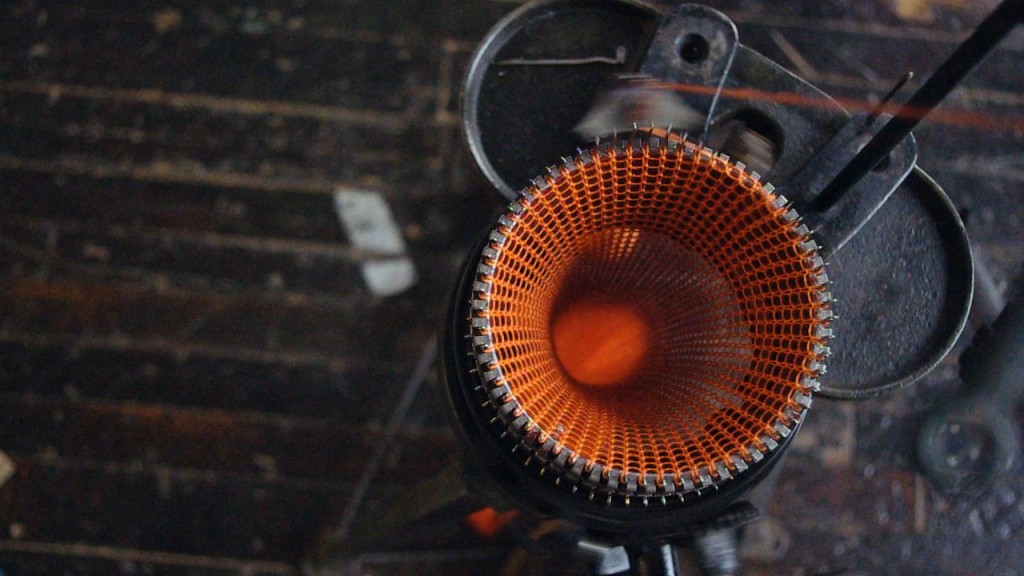

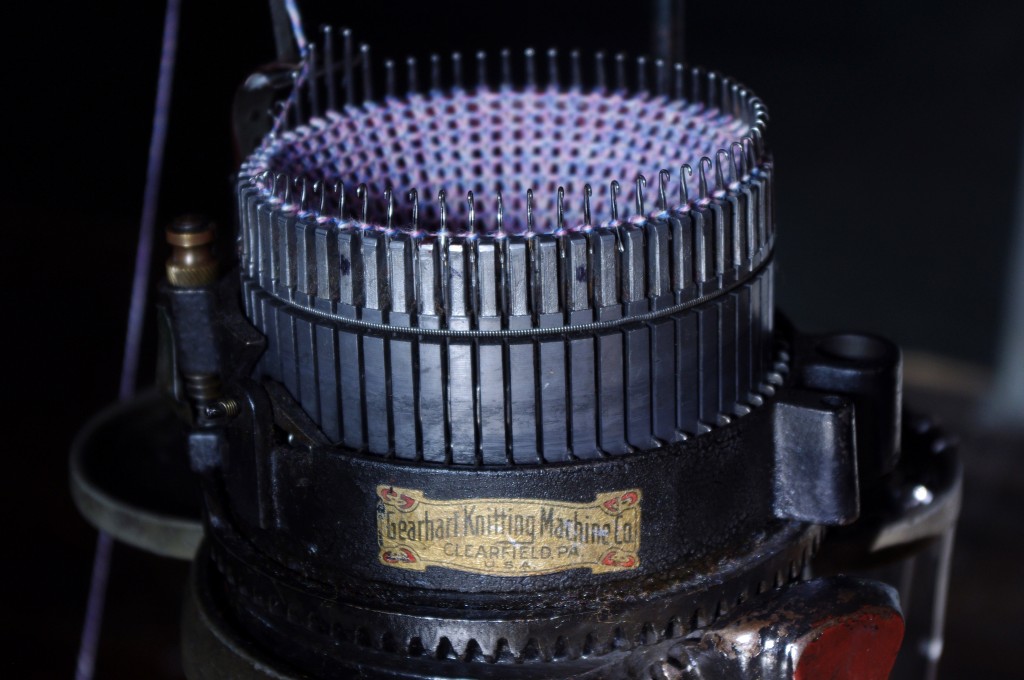

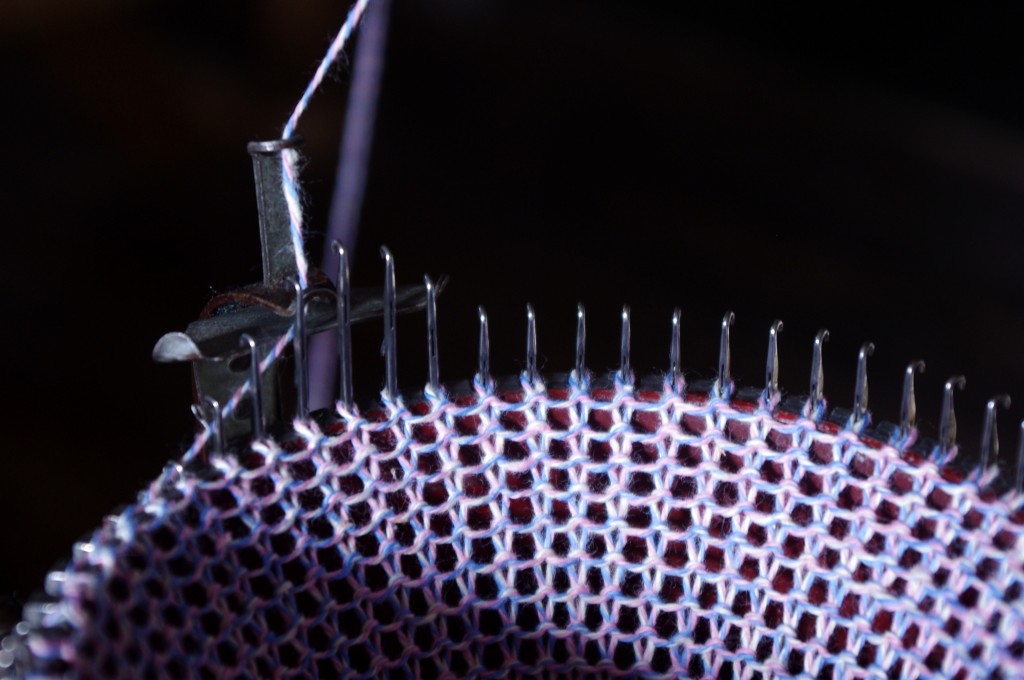

Turn the crank of the Gearhart Knitting Machine and the yarn carrier clicks around in a circle. A cam carries the latch needles up and back down again. Yarn unravels from the spool and the machine’s delicate hooks loop it through and through again. Turn the crank of the Gearhart Knitting Machine and a sock forms by the ingenious magic of careful engineering.

I rebuilt this 1908 Gearhart knitting machine while I was at the American Textile History Museum. It was the first of the museum’s textile machines that I learned to operate and it is still my favorite. Like many of the best examples of mechanical engineering, the mechanism is simple and robust. This machine has worked reliably for more than a century and needs little maintenance or adjustment. Its motion is beautiful and hypnotic. I made this short video as an ode to my favorite machine.

Automatic Knitting

The Gearhart Knitting Machine was one of several similar machines designed at the turn of the 20th century to adapt industrial knitting machinery to home use. As with sewing machines, new mass production techniques made it possible to make these complex machines inexpensively. Gearharts were marketed as “The People’s Knitting Machine” and in 1891 cost as little as $6.00. They reached a peek of popularity during and immediately after World War I.

Hand-cranked knitting machines show the on-going relationship between industrial and home production. Aspects of the machine’s design came directly from industry, but owners of these machines could also become part of a “homework” economy. Gearhart owners could sell excess socks back to the company, who would sell the socks they gathered to stores, and during World War I, the Red Cross organized volunteers into make-shift factories to knit socks for soldiers. The Gearhart, and similar machines, brought a small and manageable part of the factory into the home. The appeal of this machine might be the glimpse it allows of the beauty of mechanism and motion usually hidden away in the mills.